Introduction

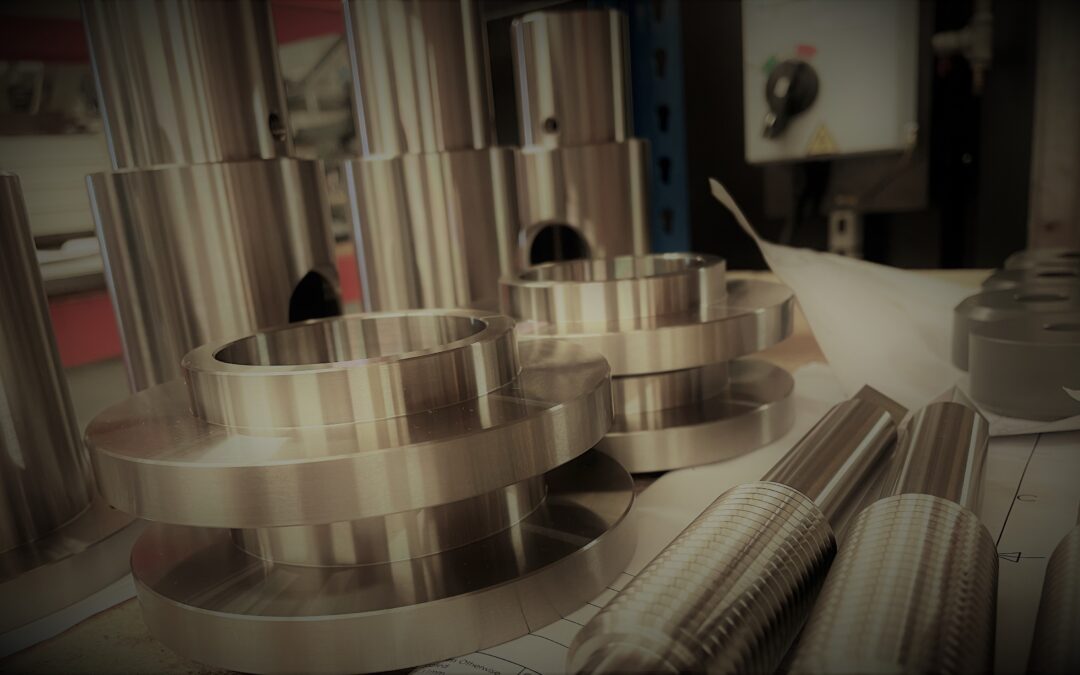

At Springfield NE, we are dedicated to enhancing manufacturing efficiency with our bespoke engineering solutions. This post delves into our custom automated product assembly machines, designed to streamline and optimize the assembly process for businesses that prioritize precision, speed, and adaptability. Explore how our tailored solutions can transform your assembly line operations.

Custom-Made Automated Assembly Machines: Engineering for Excellence

Our leadership in custom machinery extends to the specialized field of automated product assembly. Each machine we develop is more than a piece of equipment—it’s a comprehensive solution, meticulously tailored to integrate seamlessly into your manufacturing system. We engage closely with each client to understand the intricacies of their assembly needs, ensuring our solutions achieve unmatched levels of efficiency and precision.

Design and Customisation Process

Our process for creating bespoke automated assembly machines begins with a thorough consultation to capture the full spectrum of our client’s requirements. Utilizing advanced CAD technology, our design team crafts initial models that embody these specifications. These models undergo rigorous reviews and refinements in collaboration with our clients, ensuring every machine we produce is perfectly suited to their operational needs and enhances their production capabilities.

Capabilities of Automated Assembly Machines

Springfield NE’s automated assembly machines are highly customizable to suit various production environments. From small-scale operations requiring intricate component assembly to large-scale manufacturing needing high-speed assembly lines, our machines are equipped to handle diverse challenges. We provide a range of customizable features, such as multi-function assembly stations, precision robotics, and integrated quality control systems that ensure each assembled product meets stringent quality standards.

Technological Integration and Innovation

Innovation is at the heart of our automated assembly solutions. We incorporate cutting-edge technologies like robotics, artificial intelligence, and real-time data analytics to enhance the automation process. These technologies allow for greater control, faster turnaround times, and more consistent product quality. By implementing state-of-the-art systems, our machines not only meet the current demands of modern manufacturing but also offer flexibility to adapt to future advancements.

Benefits of Choosing Springfield NE for Automated Product Assembly

Opting for Springfield NE to develop your automated assembly systems guarantees a partner who understands the importance of precision and efficiency in manufacturing. Our custom machines are designed to deliver numerous operational benefits, including:

- Enhanced Production Speed: Our automated systems significantly reduce assembly time, enabling higher throughput.

- Consistent Quality: Automation minimizes human error, ensuring each product is assembled consistently to the highest standards.

- Reduced Operational Costs: Increased efficiency and reduced labor costs result from the high degree of automation.

- Scalability: Our machines are designed to grow with your business, providing easy upgrades and expansions as your needs evolve.

Conclusion

Automated product assembly machines from Springfield NE are not just part of your production line; they are key to transforming your manufacturing capabilities. Our commitment to delivering customized, cutting-edge solutions makes us a leader in the industry. If you are looking for a reliable, innovative, and precise engineering partner, Springfield NE is your optimal choice. Let us help you elevate your assembly process and achieve new levels of manufacturing excellence.