Introduction

At Springfield NE, we specialize in developing custom bottling machinery designed to enhance the efficiency and reliability of production lines in the beverage industry. This post will explore how our bespoke bottling solutions can transform your bottling operations, ensuring they are optimized for speed, precision, and adaptability to meet your specific needs.

Custom-Made Bottling Machinery: Tailored for Your Production Line

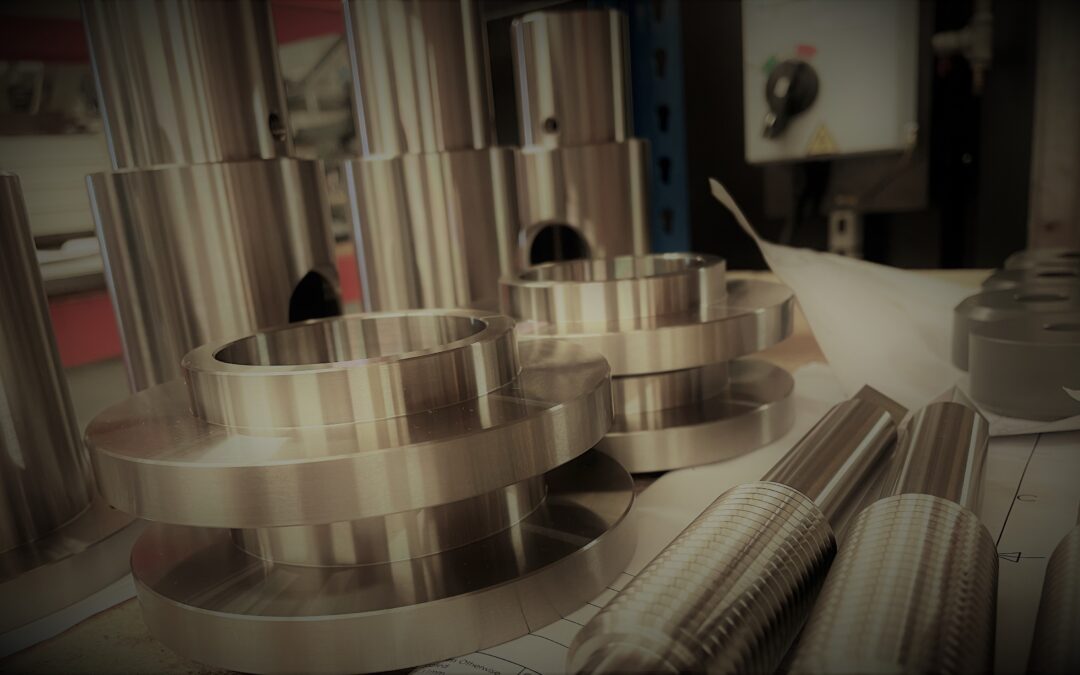

Understanding that each beverage production line has its own set of unique challenges, we provide custom bottling solutions that are meticulously crafted to address each specific requirement. Our approach involves closely collaborating with our clients to ensure that every aspect of the bottling process is enhanced by our machinery, from filling and capping to labeling and packaging.

Design and Customisation Process

The customisation process at Springfield NE starts with a comprehensive assessment of your current bottling operations. Our team of experienced engineers works directly with you to identify any potential areas for improvement and to understand the specific characteristics of the products you handle. Using cutting-edge CAD technology, we then design a bottling system that integrates seamlessly with your existing production line, ensuring that each component is optimally configured for your operational needs.

Capabilities of Custom Bottling Machinery

Springfield NE’s custom bottling machinery is versatile and built to handle a wide range of bottle sizes, types, and liquids with varying viscosities. Our systems can be equipped with:

- Precision Filling Systems: Designed to deliver exact fill levels, reducing waste and ensuring consistent product quality.

- High-Speed Capping Solutions: Capable of securely sealing bottles at high speeds to maintain throughput and extend product shelf life.

- Advanced Labeling Technologies: Including shrink sleeve, wrap-around, and self-adhesive options that can be adjusted for various label sizes and bottle contours.

- Integrated Packaging Functions: Streamlining the final stages of production by automating boxing and palletizing processes.

Technological Integration and Innovations

We leverage the latest innovations in bottling technology to provide systems that are not only efficient but also intelligent. This includes the integration of IoT capabilities for real-time monitoring and control, which allows for immediate adjustments and minimizes downtime. Energy-efficient components and sustainable operation practices are also central to our designs, supporting your company’s commitment to environmental responsibility.

Benefits of Choosing Springfield NE for Custom Bottling Machinery

Selecting Springfield NE as your partner in bottling machinery provides numerous benefits:

- Enhanced Production Efficiency: Our machines are designed to maximize throughput while maintaining the highest quality standards.

- Reduced Operational Costs: By improving the precision and efficiency of the bottling process, our machinery helps to lower production costs over time.

- Custom Adaptability: We ensure that each system is flexible enough to adapt to future product changes, whether it’s different bottle sizes, new product lines, or updated packaging styles.

Conclusion

Custom bottling machinery from Springfield NE represents a significant advancement in your production capabilities. Our commitment to developing tailored, innovative solutions ensures that we remain leaders in the bottling industry. For businesses looking for a reliable, efficient, and precise engineering partner, Springfield NE is your go-to source. Let us help you elevate your bottling operations to meet the dynamic demands of today’s markets and beyond.