Introduction

At Springfield NE, we specialize in the design and manufacture of custom conveyor systems that streamline and enhance the efficiency of industrial operations. This post will delve into how our tailored conveyor solutions can transform your production workflow, ensuring optimal performance and adaptability to your specific operational needs.

Custom-Made Conveyor Systems: Engineered for Efficiency

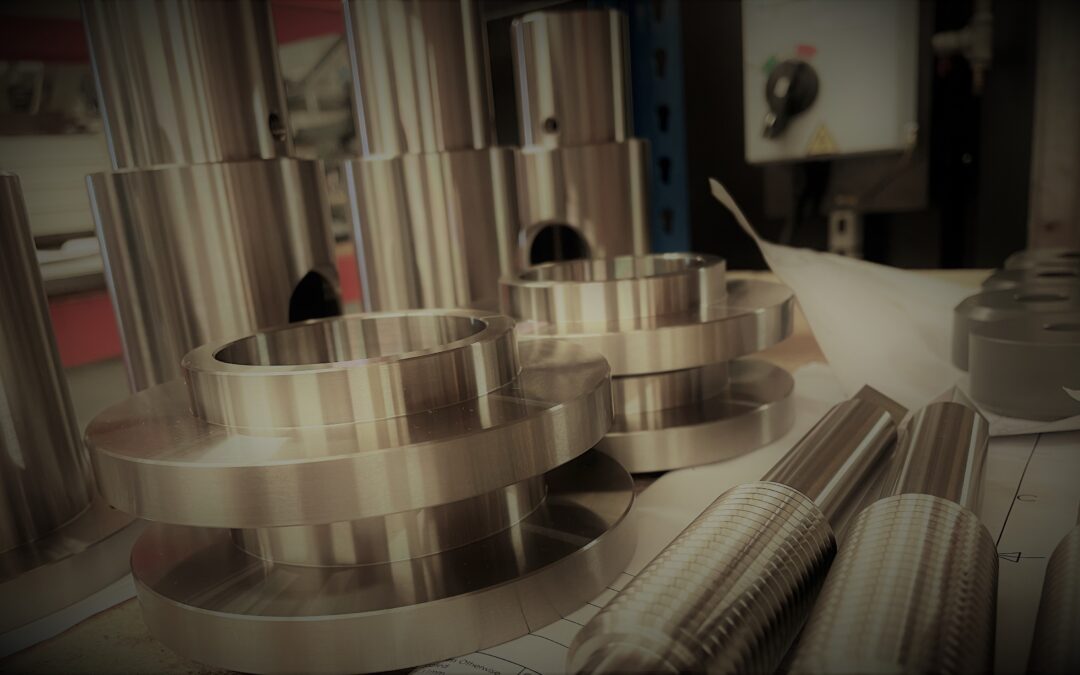

Conveyor systems are crucial in many industries for the seamless transportation of materials and products. At Springfield NE, we recognize the importance of bespoke solutions in these systems to address the unique challenges of different industrial environments. Each system we develop is designed with precision, incorporating specific features and technologies to meet the distinct requirements of our clients.

Design and Customisation Process

The customization process at Springfield NE begins with an in-depth analysis of our client’s operational needs. Our engineering team collaborates closely with clients to understand the specifics of their material handling requirements. Utilizing advanced design software, we create initial schematics that reflect these requirements. These designs undergo multiple iterations, with ongoing client feedback, ensuring the final conveyor system is perfectly aligned with their operational goals and integrates seamlessly into their existing processes.

Capabilities of Custom Conveyor Systems

Our conveyor systems can be tailored in numerous ways to suit a wide array of industrial applications. We design systems that range from simple belt conveyors to complex automated conveyor networks featuring:

- Variable Speed Controls: To handle different production rates and material types efficiently.

- Multi-directional Conveyors: Designed to change the flow direction of materials, accommodating complex plant layouts.

- Robust Material Options: Including stainless steel and reinforced polymers for durability and compliance with industry standards, particularly in food processing or pharmaceuticals.

Technological Integration and Innovation

Innovation is key in our conveyor designs. We integrate the latest in automation and control technologies to enhance the functionality and efficiency of our systems. This includes the use of IoT-enabled devices for real-time tracking and diagnostics, advanced sensors for load and speed adjustments, and energy-efficient motors that reduce the overall carbon footprint of the operation.

Benefits of Choosing Springfield NE for Custom Conveyor Systems

Choosing Springfield NE for your conveyor system needs offers several advantages:

- Tailored Efficiency: Each system is specifically designed to optimize the flow of materials in your facility, enhancing productivity and reducing bottlenecks.

- Scalability: Our systems are designed to grow with your business, accommodating future expansions or changes in production easily.

- Reduced Downtime: By using high-quality materials and smart designs, our conveyors require less maintenance and are less prone to breakdowns, ensuring continuous operation.

Conclusion

Custom conveyor systems from Springfield NE are more than just components of your production line; they are critical to enhancing operational efficiency and adaptability. Our commitment to delivering tailored solutions and our expertise in advanced manufacturing techniques make us a leader in the industry. For businesses seeking reliable, innovative, and precise engineering solutions, Springfield NE is your partner in achieving optimal productivity. Let us help you transform your industrial operations with a conveyor system designed specifically for your needs.