Introduction

At Springfield NE, we specialize in providing custom engineering solutions that enhance operational efficiency across diverse industries. In this post, we focus on our bespoke packaging machines, which are central to optimizing the packaging processes for businesses requiring precision, reliability, and adaptability. We’ll explore how our approach to custom machinery meets and exceeds the unique packaging demands of our clients.

Custom-Made Packaging Machines: Tailoring Success in Packaging Operations

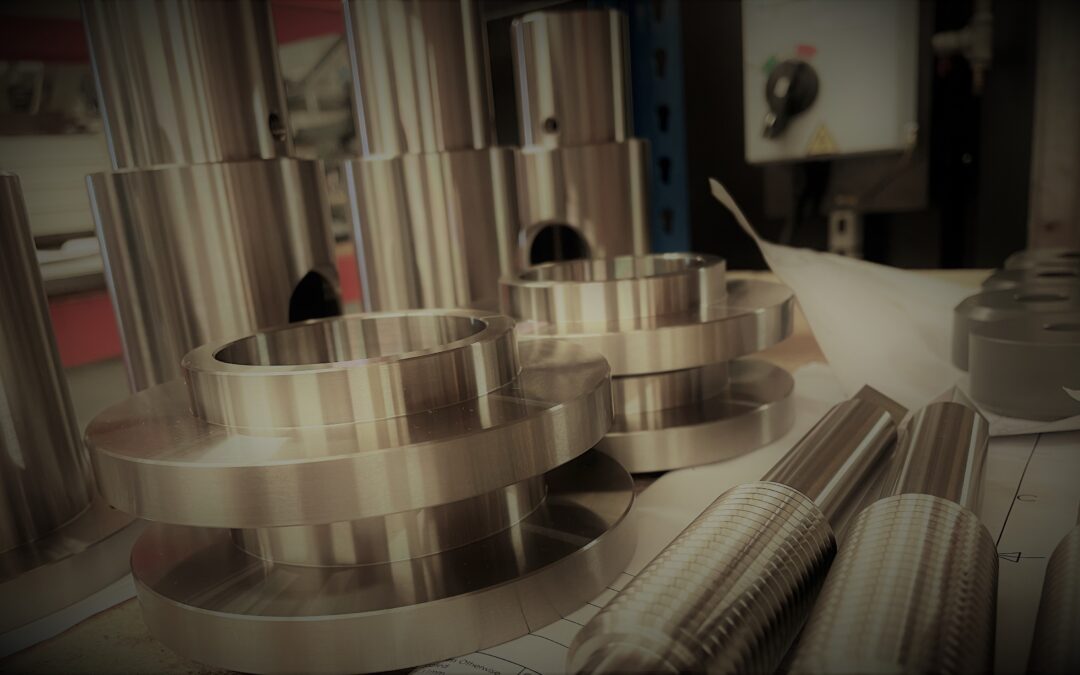

Our position as a leader in the engineering field extends to our expertise in packaging machine technology. These machines are not just equipment; they are customized solutions crafted to meet the specific challenges and requirements of our clients. By engaging deeply with each client, we understand their unique packaging needs, translating these into highly effective, bespoke packaging solutions.

Design and Customisation Process

The customisation process for our packaging machines starts with a detailed understanding of the client’s packaging needs, from the initial product handling to the final packaging stages. Our design team uses sophisticated CAD tools to create initial concepts, which are refined through client interactions to ensure complete satisfaction. This iterative design process is crucial for developing machines that not only fit seamlessly into existing production lines but also enhance operational throughput and reliability.

Capabilities of Custom Packaging Machines

Springfield NE’s packaging machines can be tailored to handle a wide range of materials and packaging styles, from rigid boxes to flexible wrappers and everything in between. We offer customization in automation levels, speed settings, and modular designs that allow for easy upgrades and changes based on future needs. These machines are equipped to perform tasks such as filling, sealing, wrapping, and labeling, all configured to operate within the specific parameters required by our clients.

Technological Integration and Advancements

We incorporate the latest in packaging technology into our machines, including smart sensors for precision filling and sealing, programmable logic controllers for streamlined operations, and machine learning algorithms to optimize packaging speed and material usage. These technological enhancements not only improve the efficiency and quality of packaging but also reduce waste and operational costs.

Benefits of Choosing Springfield NE for Custom Packaging Machines

Selecting Springfield NE for your custom packaging machinery needs ensures you receive a solution perfectly aligned with your operational requirements. Our client-focused approach guarantees that each machine not only meets but exceeds performance expectations. The reliability, efficiency, and adaptability of our machines provide substantial improvements in productivity and a significant reduction in downtime.

Client Success Stories

Our tailored packaging machines have revolutionized production lines for many clients. For instance, we developed a specialized packaging solution for a food manufacturer which increased their packaging efficiency by 50% and reduced packaging material costs by 20%. These achievements highlight our ability to design and deliver packaging solutions that provide real competitive advantages.

Conclusion

Custom packaging machines from Springfield NE are more than just components of your production line; they are key to achieving optimal efficiency and effectiveness in your packaging operations. Our commitment to bespoke solutions and our extensive experience in tackling diverse packaging challenges make us a leader in the industry. For those in search of a reliable, innovative, and precise engineering partner, Springfield NE is the definitive choice. Let us help you transform your packaging process and drive your business forward.