Introduction

At Springfield NE, we excel in delivering custom engineering solutions that enhance manufacturing processes across various industries. This post is dedicated to our custom press machines, which play a pivotal role in shaping materials and components with precision and efficiency. We’ll explore how our innovative approach tailors these machines to meet the unique production demands of our clients.

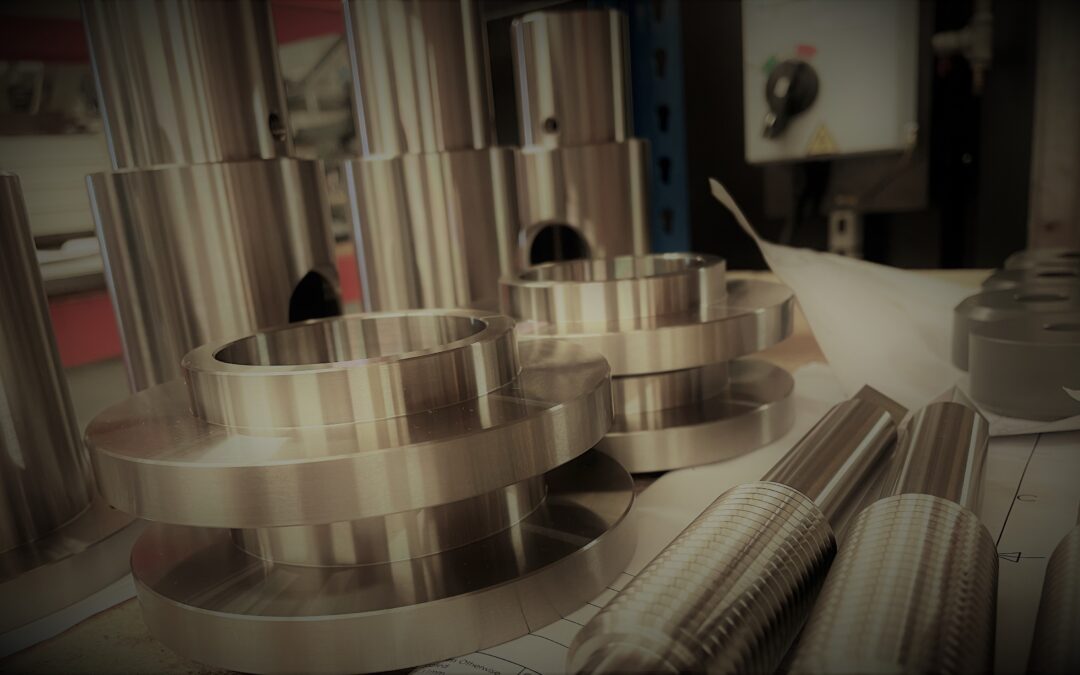

Custom-Made Press Machines: The Backbone of Modern Manufacturing

Our expertise in press machine technology distinguishes us in the engineering field. These machines are not merely production tools; they are precision-crafted solutions, designed and built to tackle specific manufacturing challenges. Through close collaboration with our clients, we gather detailed operational requirements, translating them into bespoke technical solutions that truly align with their production goals.

Design and Customisation Process

Our process for customising press machines begins with a comprehensive consultation to understand each client’s specific needs and constraints. Our skilled design team employs advanced CAD software to create initial drafts, which are then refined through ongoing client feedback to ensure every detail aligns perfectly with their expectations. This collaborative design process is essential for producing machines that integrate seamlessly into clients’ existing workflows and enhance their overall production capabilities.

Capabilities of Custom Press Machines

Springfield NE’s press machines can be customised extensively to address a variety of manufacturing tasks. From the physical dimensions and pressure capacity to specialised features like heat integration or multi-stage pressing options, our machines are designed to be versatile and adaptable. We equip them with the latest automation technology to ensure they can handle complex, high-volume tasks with exceptional precision and efficiency.

Technological Innovations in Press Machine Engineering

We are committed to incorporating cutting-edge technologies into our press machines. This includes the integration of IoT (Internet of Things) capabilities for enhanced monitoring and control, as well as the use of superior materials that increase durability and performance under rigorous operational conditions. Our innovative use of technology not only meets current manufacturing needs but also provides scalability for future advancements.

Benefits of Choosing Springfield NE for Custom Press Machines

Opting for Springfield NE means choosing a partner who understands the importance of precision and reliability in manufacturing. Our custom press machines are designed to provide significant operational benefits, including increased productivity, reduced downtime, and lower maintenance costs. Our client-centric approach ensures that each machine we deliver exceeds the specific performance expectations set by our clients.

Client Success Stories

Our custom press machines have been instrumental in transforming production processes for numerous clients. For example, a custom solution we developed for the aerospace industry allowed for the precise shaping of composite materials, reducing material waste by 30% and improving the overall manufacturing time by 25%. These success stories underscore our ability to deliver solutions that not only meet but exceed the evolving demands of modern industries.

Conclusion

Custom press machines from Springfield NE represent more than just engineering achievements; they are critical tools that drive manufacturing efficiency and innovation. Our unwavering dedication to developing tailored solutions and our proactive approach to client collaboration ensure that we continue to lead in the industry. For anyone seeking a reliable, innovative, and precise engineering partner, Springfield NE is your go-to choice. Together, we can push the boundaries of what is possible in manufacturing technology.